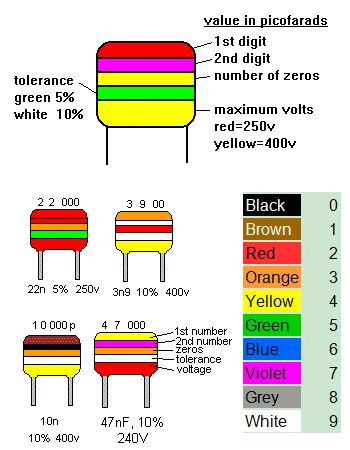

Basics of Capacitor MarkingsĪs discussed above, there are various factors and standards which are followed while marking the capacitors. The EIA (Electronic Industry Alliance) has also been playing a crucial role in providing standardized systems of marking the capacitors which can be followed as a standard in the industry. Another factor which plays a role in deciding the marking is the size of the capacitor as it impacts the space which is available for capacitor’s marking.

The component deciding the coding can be surface mount, technology, traditional lead, or capacitor dielectric component. The type of component acts as a deciding factor of the types of the codes used. The markings’ format is dependent upon what type of capacitor is given. There are various different ways in which the marking is done on the capacitors. Some of these markings and codes include capacitor polarity marking capacity colour code and ceramic capacitor code respectively.

The various parameters of the capacitors such as their voltage and tolerance along with their values is represented by different types of markings and codes.

0 kommentar(er)

0 kommentar(er)